Also there is stroke switches on the mould to be sure the ejection return strokes are correct. We have designed the electronic eye on the PET Preform Molds to be sure that if there is some preform has not drop down, the mould will not closed. By this way we can reduce around 10 seconds for each cycle. In one cycle time, for example 28 seconds, the cooling time take 12 seconds, for this reason, we have considered to make the cooling outside of the mould by one vice cavities group, on these vice cavities, we used chilling water on it. We considered the mould running speed from the mould design, such like injection system, guiding system, ejection system and cooling system. PET Preform Mold injection molding speed.PET Preform Mold’s components are interchangeable.ĭue to the high precise machining and rigorous dimensions controlling, in our PET Preform Mold all the same parts realized interchangeable, and for so many components which are same in different moulds, we kept them as the stocks for faster delivery time and prompt services to our customers.

Before the components moving to assembling workshop, the QC department will make one more time measuring to be sure the dimensions are meeting the drawing’s tolerances. When the parts on the machines, it was measured to be sure the dimensions are meeting our tolerance. All the components of the mould will be made accordingly to our 2D prints tooling drawings, on the the drawing, there are tolerances, tooling process, material hardness…all the details. We have invested more than 1 millions tooling machines from Europe and Japan which are especially for PET Preform Mold manufacturing.

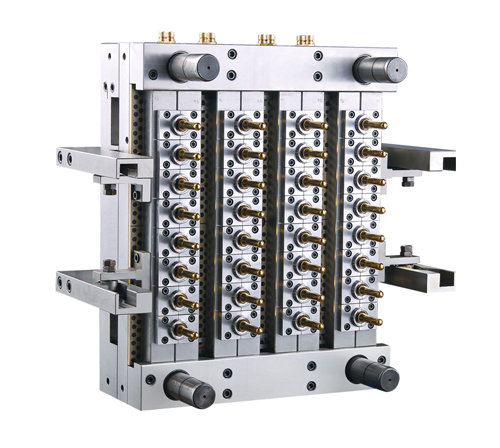

The hot runner system of PET Preform Mold is one of the key points, HYX MOULD has a very special PET molding valve gate system which can avoid material leakage…it can say one of the best PET hot runner system in world. PET Preform Mold valve gate injection system R&D.PET Preform Mold, from 32 to 64, to 72…up to now, we have successfully offered 128 cavities PET Preform Mold and will continues to develop 160 cavities in 2010 year. HYX MOULD has more than 15 PET Preform Mold designers, we had the technical meeting by each week in the past 6 years, in the technical meeting, we improved to our ready made mould structure and develop higher cavities nr. PET Preform Mold multi-cavities mould design improvements.It is because we know how, and we do what should be done. By offering the top quality solutions of PET PET Preform Molding to the market, HYX MOULD has won high praise from the market. Constant technological improvement, technological innovation makes HYX MOULD the industry leader in PET Preform Mold.

0 kommentar(er)

0 kommentar(er)